High Performance and Pile Driving / Extracting Power!..

With ergonomic design and high performance, various capacity OMS Excavator Mounted Vibratory Hammers provide long life, problem free pile driving application.

Specially designed OVR excavator mounted vibratory hammers are easily adapted to the excavator by connection bracket produced by OMS. They are hydraulically driven by the excavators and easily operated by excavator operator. OVR series excavator mounted vibro hammers requires not any modification on the excavators. OVR series vibro hammers can be easily used with all types of pile by using the OMS range of hydraulic clamps and provides time and cost saving.

Advantages of Excavator Mounted Vibratory Hammers

- Wide product range,

- Fast, reliable and easy excavator connection,

- Ergonomic design providing practical use,

- Full safe movement around link yoke,

- High-performance and driving/extracting power,

- Minimum vibration transmission to the environment,

- Double or single clamping the steel tube piles can be driven easily and powerfully,

- Powerful, reliable and long-life.

Vibro Hammer Technical Specification – OVR – S (STANDARD SERIES)

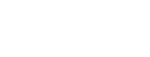

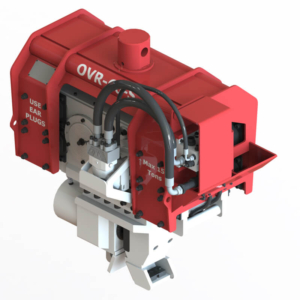

OVR 20 S (STANDARD)

OVR 20 S – SCN 20 Technical 3D Drawing Isometric

| Technical Specifications | OVR 20 S |

| Eccentric Moment (kgm) | 2,1 |

| Centrifugal Force (kN) Max. | 170 |

OVR 50 S (STANDARD)

OVR 50 S – SCN 60 Technical 3D Modelling Isometric View

| Technical Specifications | OVR 50 S |

| Eccentric Moment (kgm) | 5,2 |

| Centrifugal Force (kN) Max. | 354 |

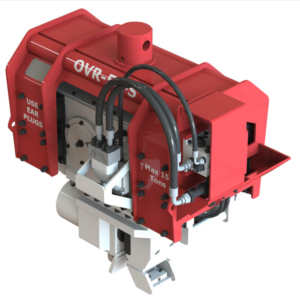

OVR 70 S (STANDARD)

OVR 70 S – SCN 75 Technical 3D Modelling Isometric View

| Technical Specifications | OVR 70 S |

| Eccentric Moment (kgm) | 7,3 |

| Centrifugal Force (kN) Max. | 607 |

OVR 120 S (STANDARD)

Excavator Mounted Pile Driver – OVR 120 S

| Technical Specifications | OVR 120 S |

| Eccentric Moment (kgm) | 12,3 |

| Centrifugal Force (kN) Max. | 1015 |

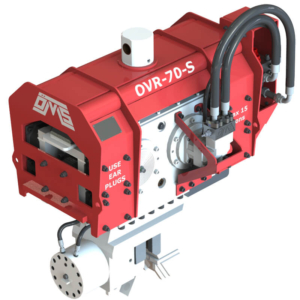

OVR 40 S (STANDARD)

OVR 40 S – SCN 30 Technical 3D Model Isometric

| Technical Specifications | OVR 40 S |

| Eccentric Moment (kgm) | 4 |

| Centrifugal Force (kN) Max. | 276 |

OVR 60 S (STANDARD)

OVR 60 S – SCN 60 Technical 3D Modelling Isometric View

| Technical Specifications | OVR 60 S |

| Eccentric Moment (kgm) | 6,3 |

| Centrifugal Force (kN) Max. | 525 |

OVR 80 S (STANDARD)

OVR 80 S – KCN 40 Technical 3D Modelling Isometric View

| Technical Specifications | OVR 80 S |

| Eccentric Moment (kgm) | 9 |

| Centrifugal Force (kN) Max. | 744 |

Technical Specifications Of Excavator Mounted Resonance Free Vibro Hammers – OVR VM (VARIABLE MOMENT SERIES)

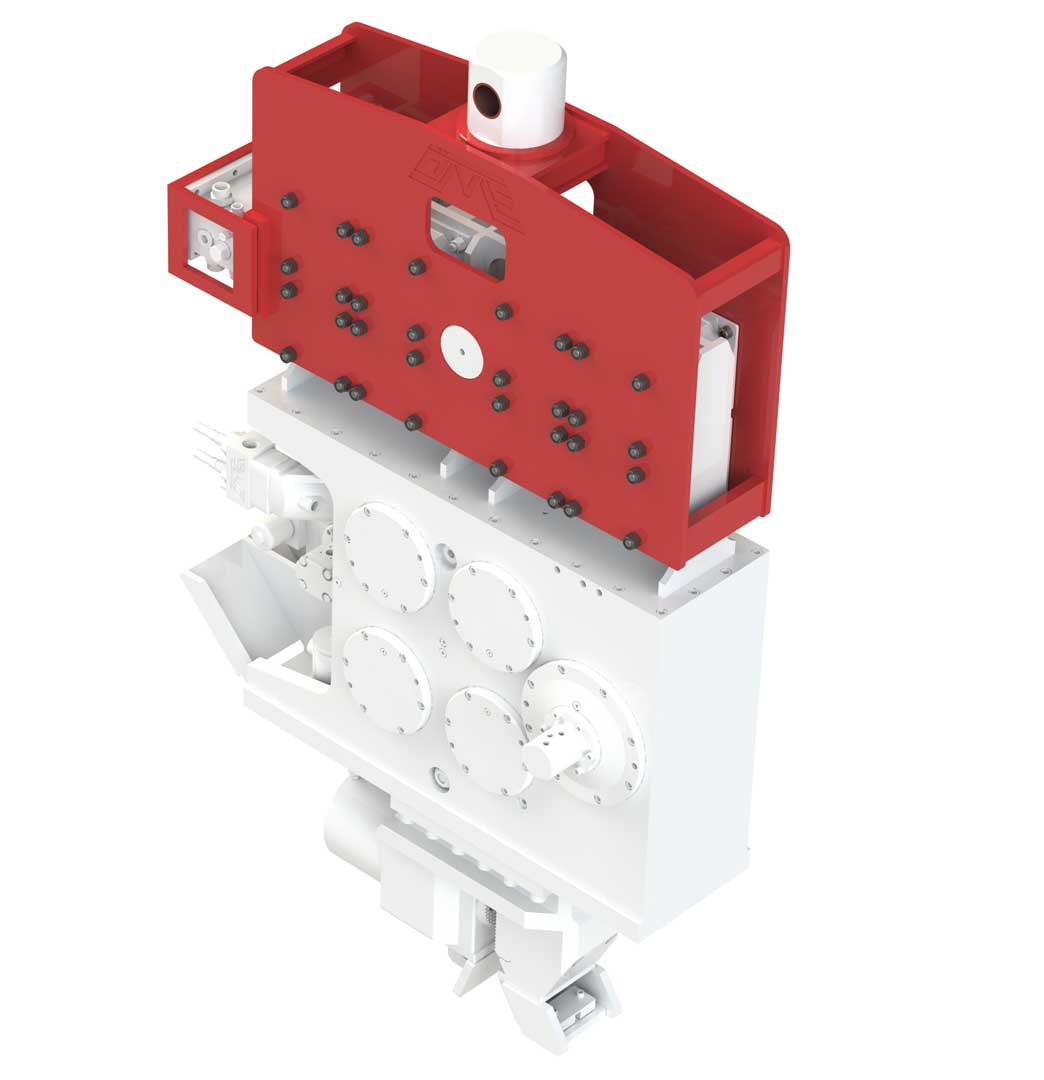

OVR 80 VM (VARIABLE MOMENT)

OMS Excavator Mounted Pile Driver

| Technical Specifications | OVR 80 VM |

| Eccentric Moment (kgm) | 0 – 8 |

| Centrifugal Force (kN) Max. | 464 |

OVR 120 VM (VARIABLE MOMENT)

OMS Excavator Mounted Pile Driver

| Technical Specifications | OVR 120 VM |

| Eccentric Moment (kgm) | 0 – 12 |

| Centrifugal Force (kN) Max. | 698 |

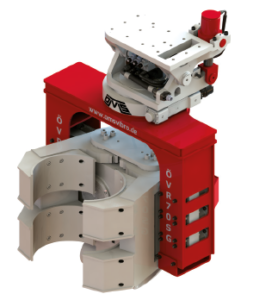

Vibro Hammer Technical Specification – OVR – SG (SIDE GRIP SERIES)

Side Grip Pile Driver 3D Technical Drawing Isometric View

Side Grip Tube Pile Driver 3D Technical Drawing Isometric View