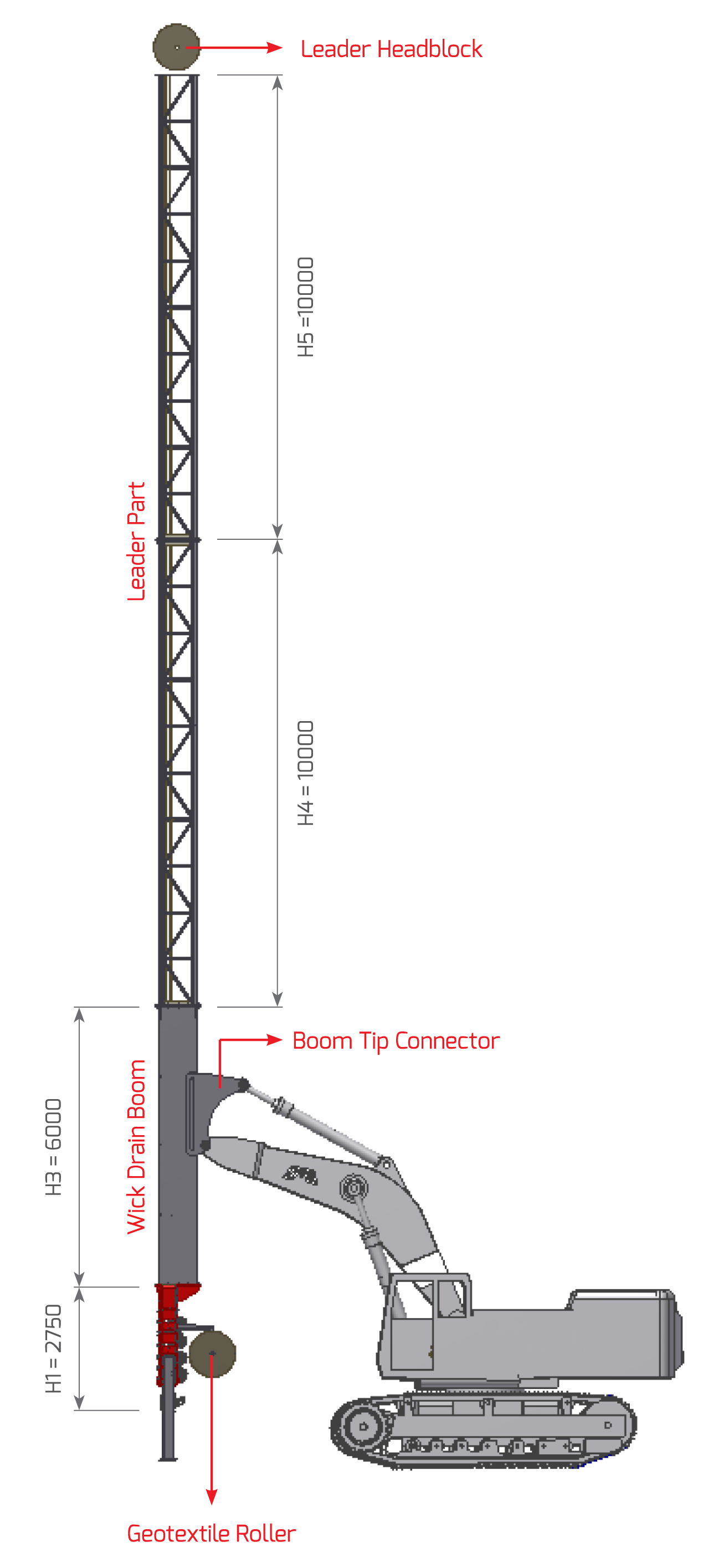

BOTTOM DRIVEN WICK DRAIN INSTALLATION MACHINE

WD 28 – 43

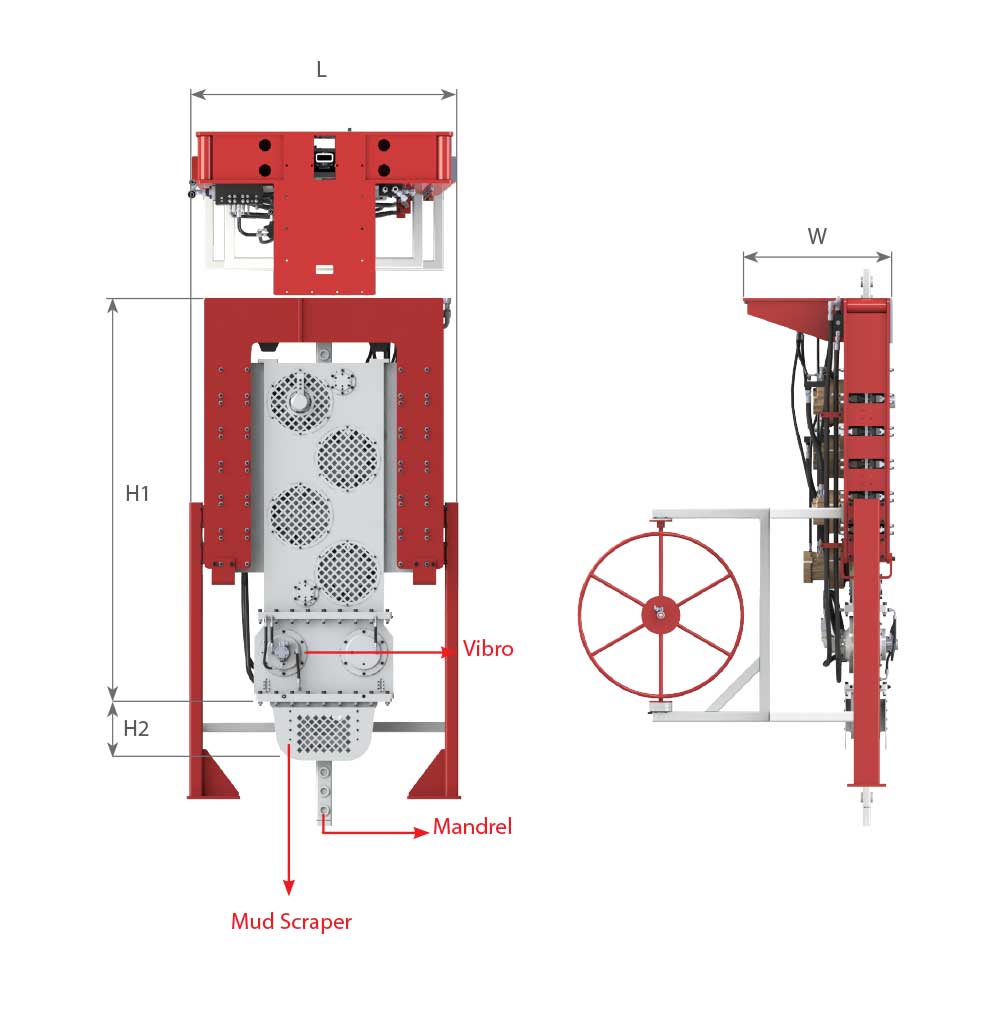

OMS Wick Drain Installation Machine is a soil improvement machine that to be used for quick consolidation of the cohesive soils. The machine is consisting of; hydromotors, sprocket gears, mandrel and a high frequency vibro hammer. It is very usefull equipment to drain the water in the cohesive soils, thus, the liquefaction risk minimal and settlement time higher then standard procedures.

Wick Drain Operation Procedure

The hydromotor driven sprocket gears insert the mandrel with Prefabricated Vertical Drain (PVD) in to the cohesive soil until the hard formation. The operator can use the high frequency vibro hammer if necessary to insert the mandrel deeper. The mandrel insert the Prefabricated Vertical Drain up to desired depth and drain stays in the soil then empty mandrel pull out and re-fill with PVD and insertion process starts again.

TECHNICAL SPECIFICATIONS (Metric)

| Static (crowd) Force (kN) | 276 |

| Dynamic Force (kN) | 435 |

| Combinded Force (kN) | 711 |

| Operating Frequency (rpm) | 2500 |

| Pressure Max. (bar) | 350 |

| Oil Flow Vibro Max. (l/min) | 200 |

| Oil Flow Wick Max. (l/min) | 506 |

| Mandrel Speed Max. (m/min) | 100 |

| Recommended Excavator Working Weight (ton) | 45 – 50 |

TECHNICAL SPECIFICATIONS (US)

| Static (crowd) Force (tons) | 31 |

| Dynamic Force (tons) | 49 |

| Combinded Force (tons) | 80 |

| Operating Frequency (rpm) | 2500 |

| Pressure Max. (psi) | 5076 |

| Oil Flow Vibro Max. (gpm) | 53 |

| Oil Flow Wick Max. (gpm) | 134 |

| Mandrel Speed Max. (in/min) | 328 |

| Recommended Excavator Working Weight (ton) | 45 – 50 |

Advantages of Wick Drain Installation Machine

- To prevent excessive settlement of cohesive soils when it is being utilised for construction purposes (roads, airports, bridge and other foundations),

- To enhance the soil stiffness in order to prevent liquefaction and subsequent damage to structures in seismic – sensitive regions,

- To succeed the project in a short time and low cost.

Request Quote!

Help us to understand your basic needs!

So we can create the best offer for you and we’ll be in contact soon!