What is Vibro Hammer?

A vibro hammer which is also known vibratory hammer is a construction equipment used to drive or extract piles into or out of the ground using vibrations. It works by transmitting high-frequency vibration energy to the pile, which causes the surrounding soil particles to become loose and reduce the resistance to pile penetration.

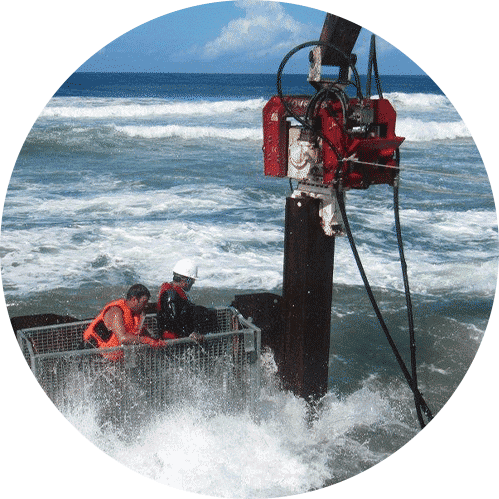

Vibratory pile drivers are commonly used to construction projects such as building harbors, bridges, marine structures, offshore wind farms, airports, roads, rails, infrastructure, solar power, wind turbines, walls and many other foundation types. Vibro hammers are modern and popular machinery for pipe, sheet and wooden piles. Therefore it is preferable in urban areas and downtowns.

There are different types of vibro hammers such as excavator-mounted vibro hammers, crane suspended vibro hammers and variable moment vibro hammers. Selection of vibro hammer type depends on the size and weight of the pile and the soil conditions at the construction site.

Modern pile drivers are quiet and have many advantages compared to traditional pile drivers which use a large weight to strike the pile. For instance the greatest advantage is that vibratory hammers can drive and extract piles much faster. Beside this, they are small, very quiet and light weight, environmental friendly. So they can drive piles much more quickly, extract old piles out of the ground, can be used underwater, are lightweight, protect the environment (especially animal life), can be used in close proximity to residential areas without noise complaints, and are small and easy to ship. Moreover, in some vibratory hammers vibration can be fully controlled, which is a necessity if the work has to be carried out in residential or historical places.

You can read about Vibratory Hammers, What Is Vibratory Hammer? and Pile Driver Types.

How Does Vibro Hammer Work?

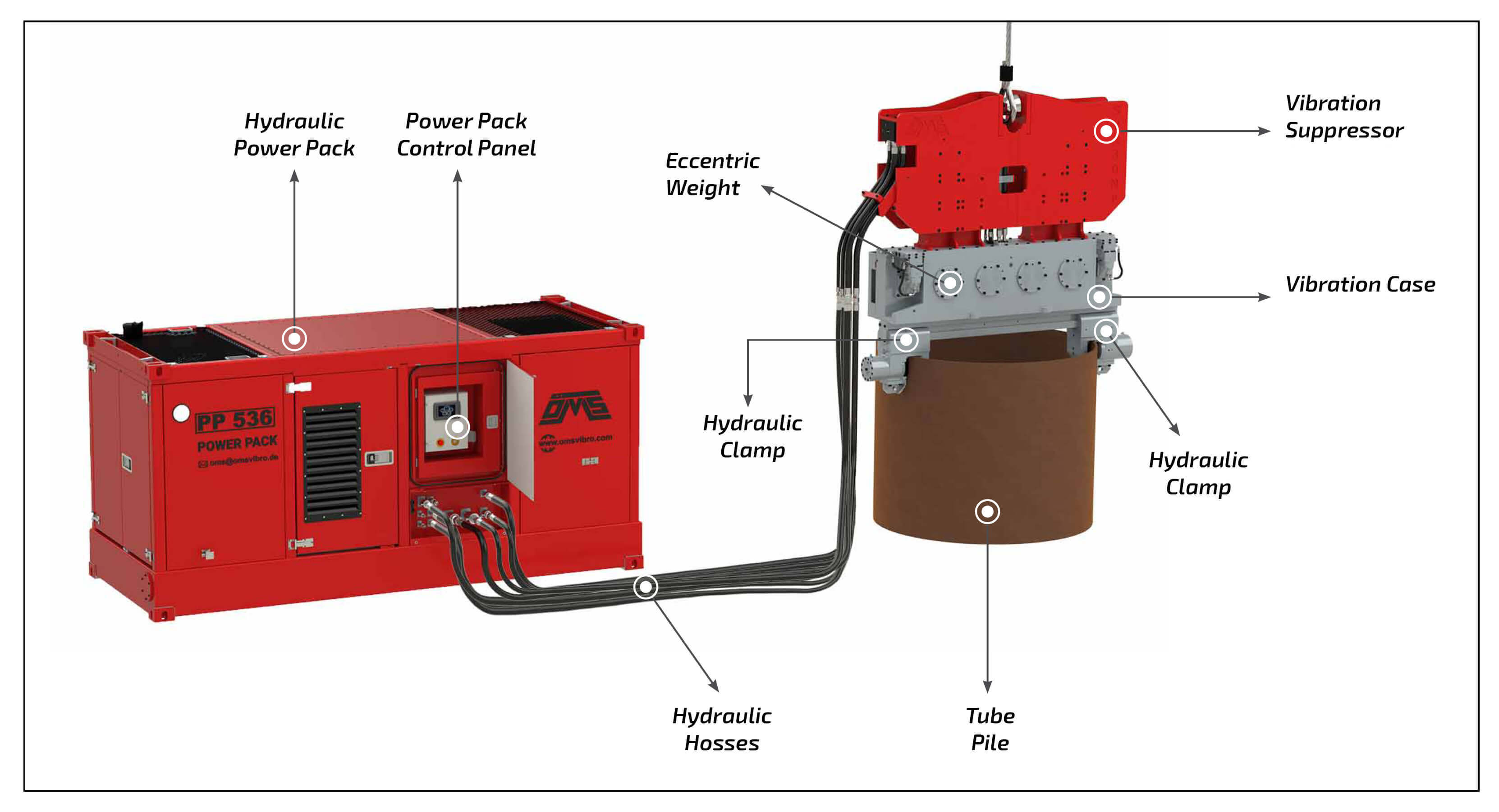

OMS Vibro Hammer Machines also known as vibro drivers and vibratory hammers work on the idea of reducing the resistance of the ground with vibration and by changing the formation of the ground. The vibratory piling machine transfers vertical vibrations to the pile via the hydraulic clamp. This, in turn, transfers vibration to the ground which reduces the friction between the pile and the ground allowing the pile to be driven or extracted with less force. The pile is driven into the ground by a combination of the vibrators weight and the centrifugal force it produces.

If you are interested in soil improvement, you may want to read How to Install Wick Drain top feed/bottom feed vibroflotation systems and stone column equipment you can read about Ground Improvement Techniques.

Illustration of Vibro Hammer Working Principle

Animation Video of How Crane Hanging Vibro Hammer Works

Working System of Excavator Mounted Vibro Hammer

Vibration Suppressor

Vibration Case

Eccentric Weight

Hydraulic Clamp

Hydraulic Clamp

Tube Pile

Types of Vibratory Hammers

Crane Suspended Vibratory Hammers

Excavator Mounted Vibratory Hammers

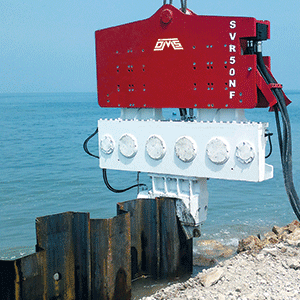

Side Grip Vibratory Sheet Pile Drivers

Advantages of Vibratory Hammers?

- Vibro hammer can save time and cost because it drives the piles faster,

- They can be used for driving and extracting the piles from the ground,

- They can be used underwater,

- It is light and user-friendly,

- They can be used depending on both the crane and the excavator.

- In projects which require high driving/dismounting capacity, crane suspended hammers which supply the needed energy through the power pack are used.

- It has environmentally-friendly technology (especially to protect the fauna).

- They supply their energy through the hydraulic or electrical energy line, but hydraulic lines are more preferred because they are lighter and stronger.

- They are small and easy to transport and maintain.

- The vibratory pile hammers are very cost effective than a commonly-used hammer drivers.

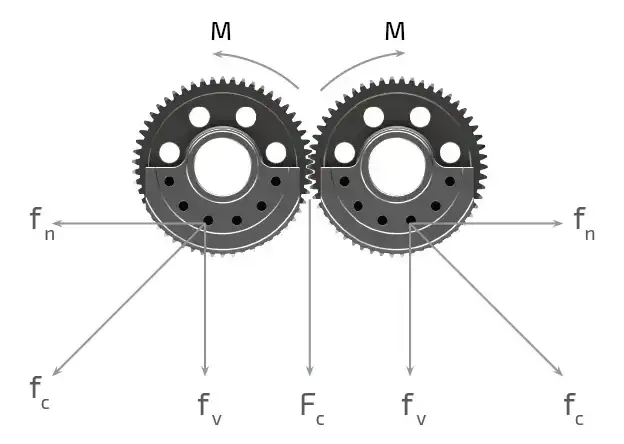

Eccentric Moment M (kgm):

The eccentric moment is calculated by the eccentric weight (m) and the distance from the centre of gravity to the rotation axis (r).

Centrifugal Force F (kN):

n: Rotational Speed of Hydraulic Motor (rpm)

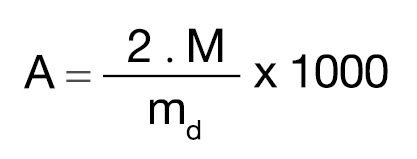

Amplitude A (mm):

Amplitude is the total vertical displacement of the vibrator during a full rotation of the eccentric weights. Amplitude at maximum rotational speed is obtained with the following formula:

Amplitude Formula

M = Eccentric Moment (kgm)

md = Dynamic Weight

Dynamic Weight:

Dynamic weight is the total weight of vibrator, hydraulic clamp and pile to be driven.

Working Principle of Vibratory Pile Drivers

Working Principle of Resonance-Free Vibratory Hammers

The “Phase Shifter Motor” patented by OMS, displaces the eccentric masses and allows adjustment of the vibration level. Eccentric masses can be adjusted from 0 to 180°. The maximum vibration level is reached at 180°.

Eccentric Masses in Balance State

The phase shifter changes the position of eccentric masses to the balance situation by remote control or control panel which means no resonance.

Eccentric Masses Shifting To Unbalance State From Balance State

The phase shifter changes the position of eccentric masses from 0° to 180° so that the vibratory pile driver can work at maximum amplitude.

Eccentric Masses in Unbalance State

180° Full Power.

Working Principle of Excavator Mounted Vibratory Drivers

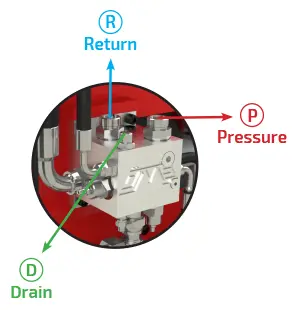

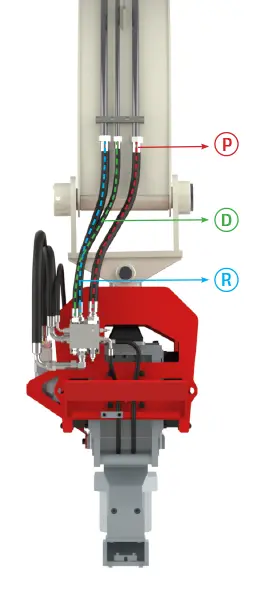

Connect the pressure and return line hoses to the flowmeter which are coming from excavator. Be sure that correct connection of hoses to flowmeter’s right ports. Adjust pressure of flowmeter with restrictor to required pressure for your vibro and with adjusted pressure regulate the required flow with excavator main pumps adjusting valve.

Install flowmeter betweeen excavator and vibrator Pressure (P) and Return (R) linehoses. Adjust and set required pressure and flow rate with excavator main pump’s adjusting valve. Drain (D) pressure should not exceed 8 bar. If the drain pressure exceed 8 bar, the rain line relief valve reliefs the pressure to prevent damaging of hydraulic motor rod seal.

Excavator Preparation

- Remove bucket pivot pin, bucket link pin and bucket.

- Remove bucket linkage pin from stick (dipper arm) and bucket cylinder pin (rod end). Remove the bucket linkage.

8 Steps To Install Vibro Hammer (For Excavator)

- Move excavator to the vibrator location. Lift, and safely support the vibrator in a vertical position.

- Check the yoke to be sure that the ears fit onto the excavator stick in the area of the bucket pivot.

- Check the fit of the yoke pin in the bucket pivot bore on the stick.

- If all fits are correct, connect the yoke to the excavator stick.

- Fully retract the bucket cylinder and turn off excavator.

- Disconnect the bucket cylinder hoses and plug them with proper size plug.

- Remove the plugs (P, R and D) from the manifold and install the excavator hoses to vibrator and tighten. Use below picture for reference.

- To bleed the air from hoses, loosen the hoses at the clamp cylinder (approximately one turn). Run the excavator on low speed, move the bucket lever/joy stick slightly to close clamp. Wait until oil flows from the connection at the clamp. When oil flows without air, tighten the connection.

Required Pressure (P) and Flow Rate (Q)

- Vibro Hammer

- OVR 20 S

- OVR 40 S

- OVR 50 S

- OVR 60 S

- OVR 70 S

- OVR 80 S

- OVR 120 S

- P (Bar) Q

- 280 – 320

- 280 – 320

- 280 – 320

- 280 – 320

- 280 – 320

- 280 – 320

- 280 – 320

- (lpm)

- 62

- 100

- 150

- 201

- 233

- 275

- 313

Request A Quote!

Help us to understand your basic needs!

So we can create the best offer for you and we’ll be in contact soon!