VIBROFLOTATION EQUIPMENT

When a vibroflotation machine (stone column equipment) is driven into the loose ground, it creates a hole. Gravel particles of a certain size are then fed into the hole, either using the top feed or bottom feed method. A stone column is then produced by compressing the gravel with vibration. This increases the supporting strength of soft and loose grounds and reduces liquefaction risk.

If you need further details read about Ground Improvement Techniques!

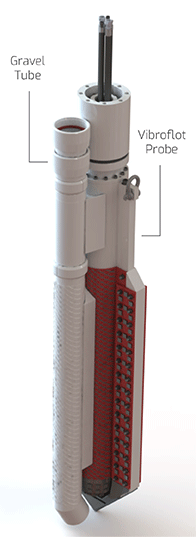

Gravel Tube Vibroflot Probe Isometric View Technical Drawing

TECHNICAL SPECIFICATIONS (Metric)

| Eccentric Moment (kgm) | 2 |

| Frequency (rpm) | 3000 |

| Centrifugal Force (kN) | 200 |

| Oil Flow (lpm) | 180 |

| Power (kW) | 105 |

| Weight (kg) | 2100 |

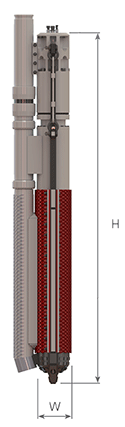

| Height (H) | 3745 |

| Width (W) | 590 |

| Length (L) | 620 |

| Power Pack | PP 218 |

| Output (kW) | 160 |

TECHNICAL SPECIFICATIONS (US)

| Eccentric Moment (in.lbs) | 174 |

| Frequency (rpm) | 3000 |

| Centrifugal Force (tons) | 22.5 |

| Oil Flow (gpm) | 48 |

| Power (hP) | 141 |

| Weight (lbs) | 4630 |

| Height/H (in) | 147 |

| Width/W (in) | 23 |

| Length/L (in) | 24 |

| Power Pack | PP 218 |

| Output (kW/hP) | 218 |

Vibroflotation Probe With Feeding Tube Front View

Vibroflotation Probe Front View

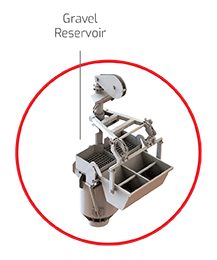

Vibroflotation Gravel Reservoir Isometric View

Control Panel

Monitors, which have a membrane keypad and LCD screen, are placed in a waterproof slot. The operator can then control the compression process parameters from the screen.

Reporting

Gauges are used for measurement, the control of vibration used in the compression of the ground and the materials and parameters of infrastructure construction.

- Column Depth

- Compression Value

- Column Diameter

- Gravel Filling Volume

Request A Quote!

Help us to understand your basic needs!

So we can create the best offer for you and we’ll be in contact soon!